Soluzioni per la Lean Manufacturing

Ruota con piastra

Ruota con foro centrale

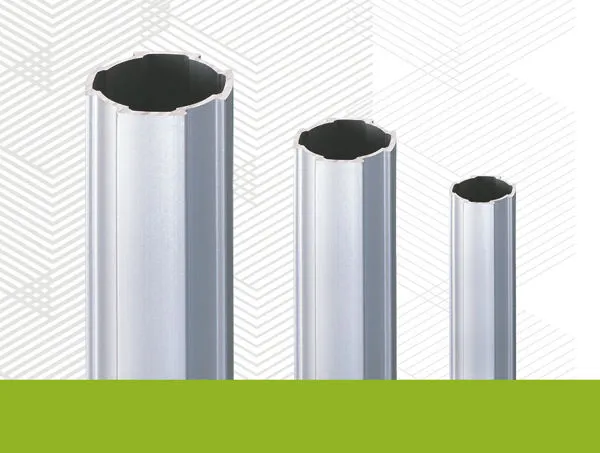

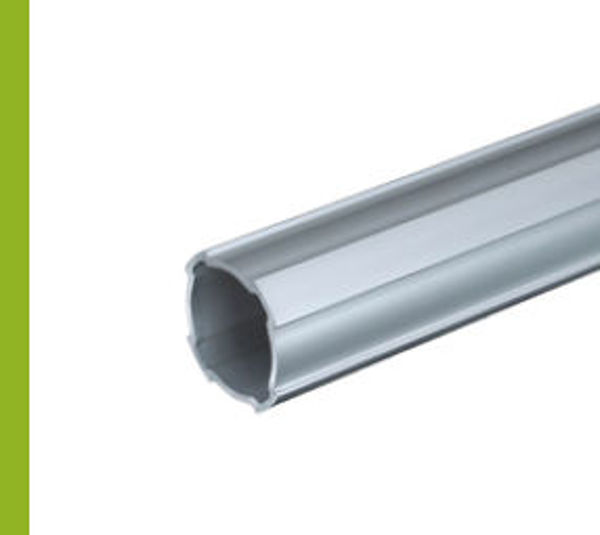

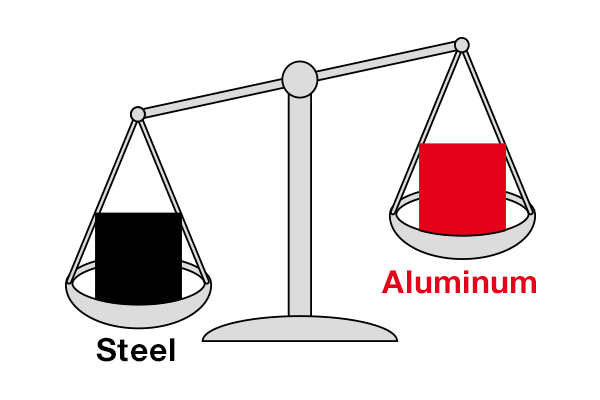

LEAN GREEN FACTORYIl sistema di profili e componenti in alluminio offre possibilità illimitate per la creazione di postazioni di lavoro, carrelli e magazzini a gravità, garantendo la massima flessibilità all'automazione industriale. I profili sono disponibili in 3 diametri differenti con un corredo di accessori per connessioni parallele e perpendicolari. La riciclabilità dei profili e relativi componenti è del 99%; il sistema produttivo è a norma RoHS. L'impatto ecologico è minimo grazie anche all'utilizzo ridotto di elettricità necessaria per raffinare un lingotto riciclato: si utilizza solamente il 3% di energia rispetto a quella necessaria per raffinare un nuovo lingotto. L'estruso in alluminio anodizzato non deposita ossidi e lascia pulito il Vostro stabilimento. La superficie antigraffio mantiene i profili lucidi a lungo. La loro particolare struttura consente un assemblaggio semplice e veloce grazie all'utilizzo di un unico punto di bloccaggio. L'estrusione di alluminio è progettata per ottimizzare l'equilibrio tra resistenza e peso, rendendola più leggera del 60% rispetto all'acciaio saldato e del 20% più resistente delle tubazioni con rivestimento in resina, agevolando lo spostamento di carrelli e magazzini a gravità. La varietà di profili ed accessori è un sistema personalizzato che garantisce ogni necessità. | ||

| ||

GREEN FRAME VS TUBOLARE RIVESTITO | ||

L'anodizzazione degli accessori elimina la manutenzione ed ha un eccellente impatto estetico, al contrario del tubolare in acciaio ricoperto il cui rivestimento in resina è soggetto a deterioramento generando polvere, ruggine e richiedendo manutenzione aggiuntiva. L'alluminio possiede naturalmente circa 1/3 della massa dell'acciaio. Il peso di ogni estrusione è inoltre ridotto dalla forma cava del Green Frame. Dato che anche connettori e accessori sono in alluminio la struttura GF rimane facile da manovrare, riducendo la tensione per gli operatori e migliorando l'ergonomia senza comprometterne la stabilità delle strutture. Comparando profilo e connettore si può sottolineare che il peso si riduce del 40%. | ||

|  | |

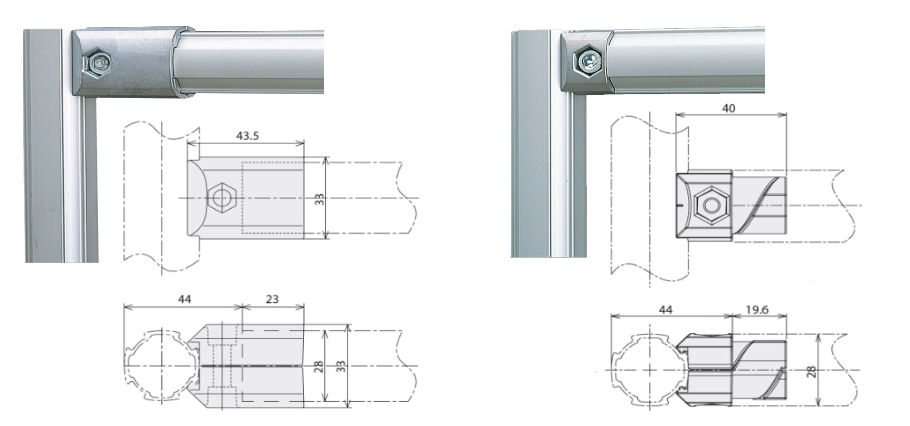

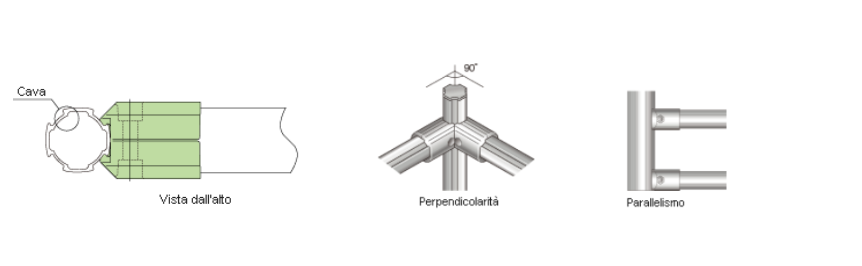

La progettazione di connettori esterni ed interni garantisce agganci anche in soluzioni con spazi ristretti. Inoltre la versione interna lascia libero il profilo e la limita l'accumulo di polvere. | ||

| ||

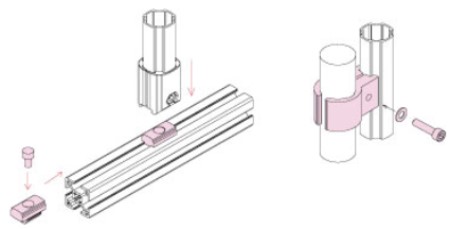

Il profilo presenta due scanalature in ognuno dei 4 angoli. Il connettore viene montato usando una sola vite rendendo agevole l'operazione e riducendo di 2/3 i tempi di assemblaggio rispetto al tubolare ricoperto. Gli accessori vengono forniti già premontati. La combinazione di profili GF leggeri e dei loro connettori versatili risponde facilmente alle esigenze degli ambienti di lavoro in evoluzione. Permette di riorganizzare le strutture in base a nuovi orientamenti, di adattarle a diversi operatori o di riutilizzare completamente i tuoi componenti GF in una nuova creazione. | ||

| ||

Non meno importanti sono gli accessori che forniscono il collegamento con profilato quadrato oppure con tubolare ricoperto pre-esistente. | ||

| ||

APPLICAZIONI | ||

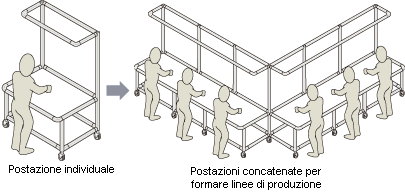

Postazione di lavoro | ||

La disposizione delle postazioni di lavoro è facile da modificare. La postazione individuale può essere facilmente integrata ad un sistema di produzione ad isole, rispettando le condizioni di lavoro e gli spazi degli operatori già presenti. Possono essere inoltre facilmente concatenate per la produzione in linea e viceversa. | ||

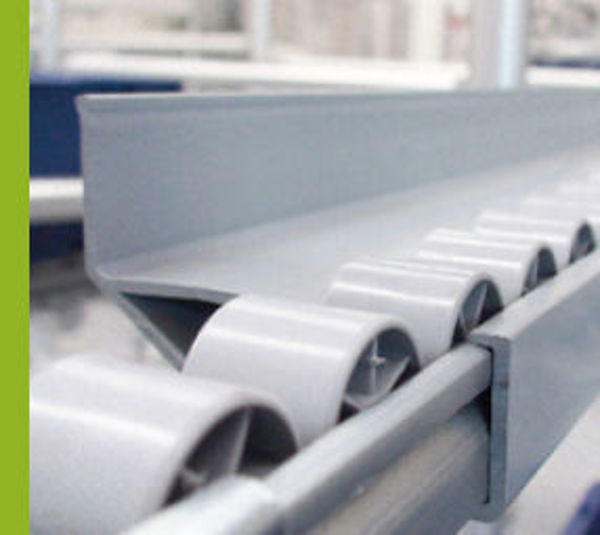

Magazzino verticale | ||

Semplice da modificare per soddisfare diverse esigenze. Adatto per essere usato come scaffalatura dove riporre componenti e contenitori. Si può ottenere un pratico magazzino verticale unendo i componenti per tratti a rulli. È possibile personalizzare l'inclinazione e la forma del secondo tipo, numero e misura del contenitore di prelievo. | ||

|

|

|

Carrello | ||

Riutilizzo con smontaggio semplice. Funzionale per il trasporto di componenti e contenitori. I profili in alluminio riducono il carico di lavoro dell'operatore e offrono la possibilità di modificare la dimensione e la forma delle composizioni. | ||

|

|

|

Camera sterile | Divisorio |

Il materiale non genera nè polvere nè ruggine. L'alluminio anodizzato con cava positiva si presta in modo particolare alla realizzazione di camere sterili in quanto non accumula polvere, non genera sfridi e non arrugginiti. | Leggeri e mobili. La leggerezza dell'alluminio è un fattore chiave per la realizzazione di divisori e pareti mobili. |

|

|

MULTIMEDIA

DOWNLOAD