Soluzioni per la Lean Manufacturing

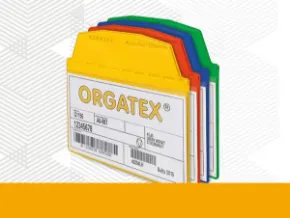

Sistema Kanban

Plastiche per Systembox A4

Cardplan® L=500 mm - Luce 30 mm

Cardplan® L=250 mm - Luce 40 mm

Cartoncini per plastiche superiori e frontali

Adattatore per systembox

Cardplan® L=500 mm - Luce 40 mm

Supporti per Systembox A4

Kit viti montaggio per supporti superiori per Systembox

Supporti orizzontali per Cardplan®

Supporti orizzontali a Z per Cardplan®

COSA É IL KANBAN

Il KANBAN è uno strumento di comunicazione nella produzione “just in time” e nel controllo del magazzino: autorizza la produzione o la movimentazione.

La parola ”kanban” in giapponese significa “cartellino visuale” o record ed il sistema è stato sviluppato da Taiichi Ohno in Toyota Motor Corporation nell'ormai lontano 1947.

Lo scopo del kanban era quello di aumentare l'efficienza e conseguentemente la produttività controllando i flussi di produzione per poter superare i concorrenti e riducendo i costi nella gestione di materie prime, semilavorati e prodotti finiti.

Il Kanban, come oggetto, quindi non è altro che un cartellino attaccato al contenitore dei componenti sulla linea che indicano/richiedono la consegna o produzione di una quantità definita. In origine il cartellino Kanban segnalava la necessità di produrre o consegnare qualcosa ma ad oggi vi sono usati diversi segnali di ripristino. Oggi, il kanban è un sistema di passaggio di informazioni che assicura che ogni stazione operativa produca solo quanto effettivamente richiesto dalla stazione a valle.

Serve come istruzione di produzione e trasferimento.

In questo modo il magazzino è sotto controllo la produzione va al passo con le spedizioni: pull system.

Il Kanban può quindi essere anche elettronico: sistemi di riordino al fornitore o al reparto produttivo che richiedono una determinata quantità di un dato materiale quando la scorta scende sotto un livello minimo prestabilito.

La quantità autorizzata da ogni singolo Kanban è minima, idealmente un pezzo. Il numero di Kanban circolanti o disponibili per un determinato oggetto dipende dalla domanda e dal tempo richiesto per produrne o acquisirne di più. Questo numero generalmente è fisso e rimane invariato a meno che la domanda o altre circostanze (per esempio i tempi di consegna del fornitore) cambino notevolmente.

Tipi di Kanban

Come strutturare il cartellino Kanban

Tutti i dati dell'articolo o del rispettivo lotto vengono riportati sul cartellino Kanban. Le informazioni di base che devono essere visualizzate sono: il codice prodotto, la relativa descrizione, il numero di pezzi in un contenitore, il cliente e il fornitore. Viene inoltre ripetuto, in questo esempio, il codice nel lato sinistro per permetterne la lettura una volta raccolto nei Systembox piuttosto che nei Cardplan®.

Download the Excel File to customize your Kanban card

Vantaggi

- eliminazione della sovrapproduzione

- riduzione delle scorte

- maggiore disponibilità di materiali

- tempi di consegna più brevi e maggiore affidabilità di consegna

- tempi di produzione ridotti

- riduzione dei tempi di pianificazione e controllo

- maggiore produttività

- meno spazio necessario nel magazzino

Multimedia

Download

Qui è possibile scaricare la sezione del catalogo dedicata