Soluzioni per la Lean Manufacturing

Material Handling

Cassettiera modulare

Contenitori RL-KLT

Modular box

Struttura per cassettiera modulare

Contenitore a bocca di lupo

Contenitore a bocca di lupo per sospensione

Contenitore abbattibile in polionda

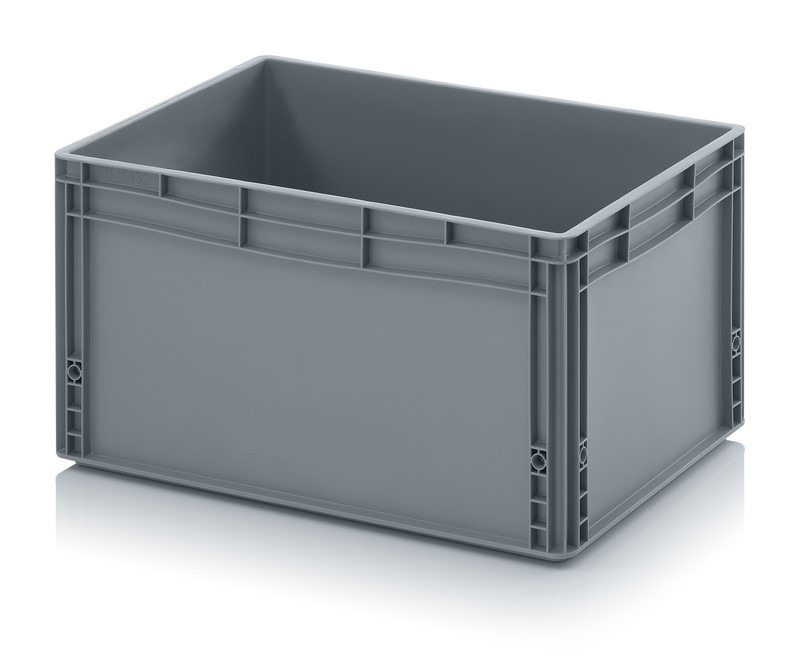

Contenitori EURO

Contenitori R-KLT

Coperchio per pallet 1200 x 800 mm

MATERIAL HANDLING

Con il termine Material Handling (movimentazione dei materiali) si identificano una serie di processi e soluzioni per la movimentazione e lo stoccaggio dei materiali che si realizza nelle aziende manufatturiere, in tutte le fasi del ciclo produttivo e della distribuzione, dalla gestione delle materie prime e componenti, alla movimentazione interna tra reparti e macchine operatrici, allo stoccaggio e preparazione degli ordini di prodotti finiti.Lo scopo del material handling è quello di rendere disponibile, attraverso l'impiego di opportuni metodi e strumenti, la giusta quantità del giusto materiale nella sua corretta collocazione, rispettando i tempi, le sequenze e le condizioni richieste e minimizzando il costo. I sistemi di material handling devono considerare anche i problemi della gestione delle informazioni associate alle merci stesse.In questa pagina vengono illustrati i sistemi di material handling che vanno dalla gestione dei componenti con contenitori, al loro trasporto tra reparti produttivi o isole di lavoro organizzato grazie all'utilizzo di binari FiFo fino alla movimentazione su nastri trasportatori. |

Contenitori

La gamma di contenitori in plastica di nostra gestione spazia dalle più piccole e pratiche cassette a bocca di lupo ai contenitori Euro o KLT per la logistica nel settore automotive, ai contenitori portaminuterie, a quelli abbattibili. Trovano impiego in tutti i settori e sono ideali per lo stoccaggio, la distribuzione e la produzione. Impilabili e/o sovrapponibili, sono disponibili su richiesta anche in versione ESD.

|  | |

I contenitori KLT sono progettati per lo stoccaggio di prodotti di piccole dimensioni e per il flusso di materiale in conformità con la norma VDA. Nati per il settore automobilistico, disponibili in varie dimensioni, con fondo rinforzato o forato, con maniglie robuste e sedi per cartellino identificativo. Possibilità di hanling automatizzato. | I contenitori EURO, in polipropilene di prima scelta, ideali per lo stoccaggio di componenti di piccole dimensioni, disponibili in varie altezze, con fondo chiuso o rinforzato per carichi più pesanti, con o senza maniglie. Hanno dimensioni di base compatibili con tutti i formati Euro attuali. | |

|  | |

I contenitori per minuteria sono ideali per lo stoccaggio di piccoli componenti. Perfetti per la preparazione di ordini, facilitano la reperibilità della merce ed il relativo prelievo. Si caratterizzano per la massima flessibilità e funzionalità. | I contenitori di grandi dimensioni, che siano abbattibili, pieghevoli o modulari soddisfano ogni esigenza anche in caso di volumi notevoli. Agevolano le operazioni di carico e scarico dei componenti in esse contenuti mantenendo ridotto l'ingombro a magazzino una volta che il contenuto è stato prelevato. |

FiFo

Il metodo FIFO rappresenta la modalità di immagazzinamento di oggetti in cui il primo oggetto introdotto è il primo ad uscire. E' logico e razionale utilizzare il metodo FIFO nel flusso logistico in quanto le prime merci o le materie prime arrivate dovranno essere le prime ad essere consumate per evitarne l'obsolescenza o la scadenza. Inoltre si differenziano in modo netto le zone di prelievo dei dolly dalle corsie FiFo (lato A) e le loro zone di ripristino (lato B). | |||||

|  |  | |||

| Lato A | Lato B | ||||

I sistemi di binari FiFo MONORAIL con rotaie in alluminio di due larghezze differenti, 40 e 55 mm, per la guida su un solo lato di carrelli e i sistemi FIFo Station in plastica gialla, con base adesiva, per la guida dei carrelli su lato o su entrambe i lati propongono due alternative per un unico risultato. | |||

|  | ||

Park Station

| A supporto e completamento troviamo le Park Station nelle vesioni in alluminio e in plastica, da fissare perpendicolarmente alla corsa dei carrelli e fermarli, trattenendo le ruote anteriori e stabilendone una determinata posizione per agevolare le operazioni di carico e scarico. | ||||

|  | |||

Multimedia

OBIETTIVO: una sola movimentazione manuale di componenti e contenitori dalla produzione fino all’utilizzo finale.