Soluzioni per la Lean Manufacturing

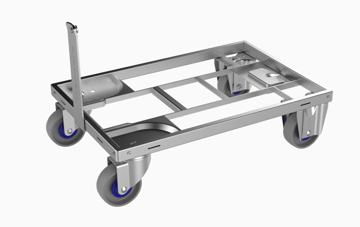

Carrelli Milkrun

Adaptor pallet

Dolly type I

Dolly type V

Dolly type VII

Dolly type VIIC

Adaptor pallet con gabbia

ASSIEME TIMONE

Cinghia per Adaptor Pallet

Coperchio per pallet 1200 x 800 mm

CARRELLI MILKRUN

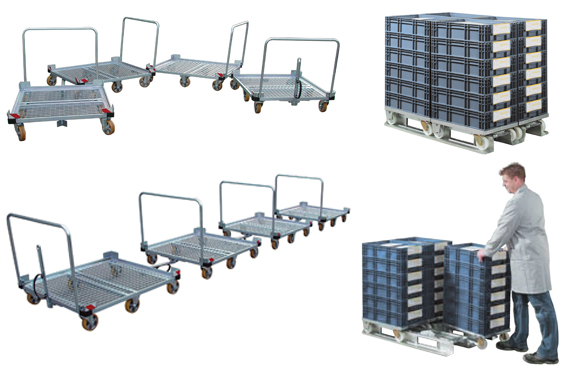

Componenti principali del Material Handling, e per questo trattati separatamente, i carrelli milkrun per la movimentazione interna sono ideali per lo spostamento di merci all’interno dell'ufficio, del magazzino o dei vari reparti e si adattano a qualsiasi settore produttivo. Sono disponibili diversi modelli, adatti alle differenti necessità. Particolarmente robusti, hanno una portata che va da 250 Kg fino a raggiungere i 1000 Kg in funzione della tipologia. La scelta del carrello adatto consente di mantenere una migliore ergonomia durante le operazioni di carico e scarico e di conseguenza una riduzione dei rischi di infortunio dovuti allo spostamento di carichi pesanti. Inoltre favoriscono una più veloce movimentazione delle merci grazie all'ottimizzazione degli spazi consentendo un risparmio in tempi e costi. I carrelli Dolly nelle loro varie versioni e dimensioni, sono dotati di timone con perno di concatenamento ad aggancio rapido: il timone dotato di perno si aggancia alla piastra di connessione che guida il perno in posizione, con una sola azione. L'aggancio resta stabile fino a quando l'operatore, con il piede, non sbloccherà il timone premendolo leggermente verso il basso. I Dolly possono essere utilizzati per la movimentazione e lo stoccaggio del materiale insieme all'Adaptor Pallet su cui si alloggiano in sicurezza grazie ad uno speciale blocco. |

TIMONE CON PERNO DI CONCATENAMENTO

|  |

| ||

| Area ampia per guidare e bloccare il perno della barra di traino. | Tirando la piastra, si guida il perno in posizione. | Perno bloccato in posizione corretta. |

Taxi Wagon, Taxiliner, LiftLiner e Carrymore completano le necessità di trasporto su lunghi percorsi interni fornendo soluzioni in cui è possibile caricare carrelli, generalmente specifici per ogni singolo modello, in modo che vengano sollevati da terra. Una tecnologie avanzata permette a questi nuovi "vagoni" di inclinarsi per accogliere o scaricare i carrelli; si riduce notevolmente il rumore da rotolamento delle ruote, si migliorano i raggi di curvatura, si promuove un ambiente di produzione senza utilizzo di carrello elevato

|  |

CARICO

| Il materiale a magazzino viene caricato su carrelli Dolly Pallet concatenati che permettono una unica movimentazione per molto materiale, o direttamente trasportato, se alloggiato sui Dolly precedentemente stoccati su Adaptor pallet, che vengono scaricati ed agganciati tra loro grazie a timone e perno di concatenamento rapido.

|

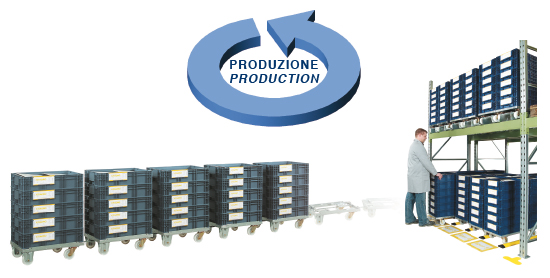

PRODUZIONE

| Il materiale trasportato dal milkrun viene portato in produzione ed assegnato secondo la logia FiFo. Il metodo FiFo rappresenta la modalità di immagazzinamento di oggetti in cui il primo oggetto introdotto è il primo ad uscire. E' logico e razionale utilizzare il metodo FIFO nel flusso logistico in quanto le prime merci o le materie prime arrivate dovranno essere le prime ad essere consumate per evitarne l'obsolescenza o la scadenza. |

MILKRUN

| Il materiale finito viene integrato al milkrun di raccolta in modo facile grazie al timone con aggancio con piena compatibilità tra i vari modelli. |

AUMENTO DELLA PRODUTTIVITA'

4 muletti devono effettuare 4 viaggi per completare il lavoro mentre con le soluzioni MilkRun basta un solo viaggio.

|

Il processo dal fornitore

|  | |

| Dalla linea di produzione i prodotti vengono collocati nei contenitori in plastica (KLT) posizionati sui dolly. | I Dolly sono collegati assieme come un trenino e trasportati in una prima zona di stoccaggio. | |

|  | |

| L’Adaptor Pallet viene caricato con 4 Dolly e poi posizionato col muletto sul camion. | ||

Il processo dal cliente

|  | |

| Gli Adaptor Pallet sono consegnati nel magazzino ingresso prodotti del cliente. | I prodotti sono collocati nel magazzino: i Dolly nella parte inferiore per un utilizzo immediato, mentre gli Adaptor Pallet con i componenti di scorta nella zona superiore. | |

|  | |

| I Dolly vengono prelevati dal magazzino e portati nella stazione di utilizzo. | Nella postazione di assemblaggio i prodotti vengono estratti dai contenitori KLT e utilizzati. I Dolly con i KLT sono portati ad un’altezza ergonomica grazie ad un elevatore di casse. |

Multimedia

OBIETTIVO: una movimentazione manuale di componenti e contenitori dalla produzione all'utilizzo finale.